This LK 45 manual cutting machine is mainly intended for cutting of preformed wire ropes. With the easy insertion due to its open design and quick operation makes this machine a convenient aid in the wire rope industry. Hydraulic wire rope cutting machines have a much lower sound level than other cutting solutions while also not producing any fumes or sparks. The machines contribute to a better work environment and a more efficient production.

LK 45 is equipped with an auto switch the motor stops automatically after the cutting operation. The machine is easily started again by pressing the foot pedal. The automatic stop is a measure to reduce the noise level as well as energy consumption even further. The machine is equipped with a safety device including a cover with inspection windows and brushes on both sides where the wire rope is inserted. This protects the operator and it is still easy to carry through the wire rope. Operation is made by the hydraulic unit with a cutting capacity of ordinary single layer round strand rope grade 1 960 up to 45 mm.

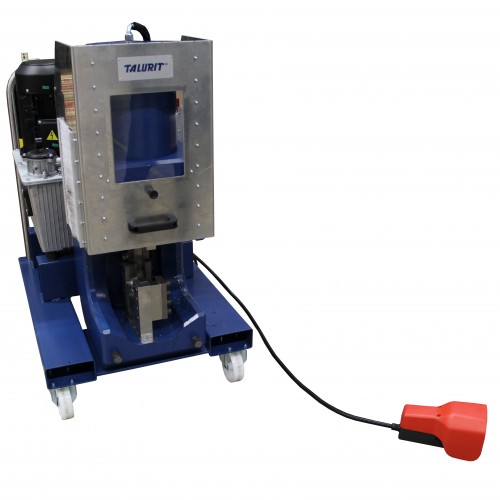

The LK 45 can either be mounted onto a wagon or a stand. Mounted on a wagon permits easy insertion of the wire rope since it is closer to the ground. The wagon makes the machine portable so that it can be moved to where the work needs to be carried out. When mounted When mounted on a stand the LK 45 is well suited for your wire rope production line.

OPTIONAL EQUIPMENT

Spare shears

Keep a spare set of shears in stock to be prepared against production downtime. The shears are easily changed.

TALURIT – Safety / Efficiency / Reliability / Quality

Talurit uses the latest techniques in engineering to ensure our manufacturing processes are to the highest quality standard, as well as highest possible safety level. Our key components are fully traceable with batch number, material certificates and quality inspections.

During development we take great pride in risk assessing our products to create a safe environment for the user, of course fulfilling the EU Machine directive and requirements for ISO 9001. On demand we can adapt this to any local standard.

All our machines are developed and manufactured in-house in our workshop in Gothenburg, Sweden, and are delivered with a full technical documentation along with instructions