LKA 28-PS is intended for cutting pre-formed wire ropes in the range Ø 5-28 mm. An optional wire rope guide can be added to extend the range to cutting from Ø 3 mm wire ropes.

The attached spouts can be extended in sections of 3 meters up to a maximum of 20 meters (longer lengths available on request).

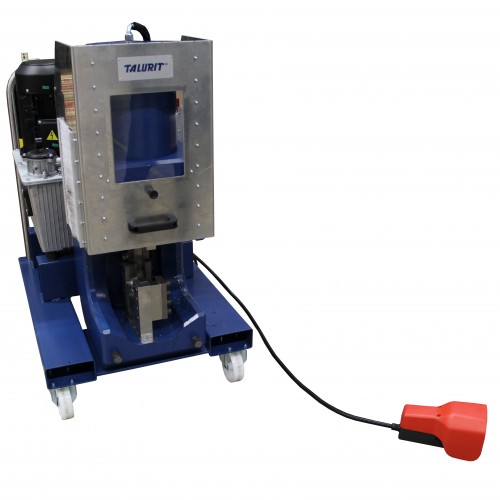

The control system is based on a PLC with a 7” touch screen. It is easy to operate due to the menu-system and it has many set-up possibilities. The feeding unit is equipped with slow start and soft retardation of the feeding speed before cut with high precision. An independent measuring system is standard to ensure very high accuracy. LKA 28-PS has a built-in calibration cycle which gives a very high accuracy on the cutting length and the repeatability is outstanding. Hydraulic shears perform the cutting operation. The shears are designed for wire ropes with maximum grade 1960. When cutting wire rope of higher grade, the lifetime of the shears will be reduced. The cutting shears are easy to change.

The machine has a very low noise level and is environmentally friendly.

OPTIONAL EQUIPMENT TO COMPLETE THE MACHINE

AVL 5000B

Uncoiling unit with brake that will cooperate with the LKA 28.

Wire rope guide – For smaller wire ropes

Adaptor that will extend the cutting range to include cutting from Ø3 mm wire ropes and up.

Marker

Marking unit that will set a mark on the wire rope at a predetermined length.

Spout

Feeding tube sections of 3 meters can be added to the machine (3 meters included) to cut straight lengths.

Popular set-ups:

1. Fully automatic cutting machine for lengths up to 20 m:

AVL 5000B + LKA 28 + Spout

TALURIT – Safety / Efficiency / Reliability / Quality

Talurit uses the latest techniques in engineering to ensure our manufacturing processes are to the highest quality standard, as well as highest possible safety level. Our key components are fully traceable with batch number, material certificates and quality inspections.

During development we take great pride in risk assessing our products to create a safe environment for the user, of course fulfilling the EU Machine directive and requirements for ISO 9001. On demand we can adapt this to any local standard.

All our machines are developed and manufactured in-house in our workshop in Gothenburg, Sweden. And are delivered with a full technical documentation along with instructions.